SideRiser 2 (SR2) is the next generation height adjuster from Chapman that is designed for the demanding bus environment.

Rigorously tested at Millbrook Proving Ground, the unit is now firmly established as the industry standard height adjuster.

The unit is completely interchangeable with the current SideRiser or older Mk250 height adjusters and has the same profile and range of adjustment.

Testing the SideRiser 2 (SR2)

Testing the new SR2 Height Adjuster was essential to ensure that the unit was durable and robust. We decided on two separate tests.

As we were using new planetary gears for the height adjustment (which was totally different from anything we have done before) we wanted to ensure that these would withstand typical operating duty cycles.

Although the adjuster is designed to be adjusted WITHOUT a driver’s weight on the seat, we added a margin of safety and weighted the unit with the equivalent of a 14 stone driver.

A typical duty cycle for the driver seat would be five drivers a day meaning that the seat would be adjusted five times a day. Some buses run 365 days a year and we believe the height adjuster should be in good safe working order for five years. Again we added a margin of safety, 10 years was the chosen duration of the accelerated life test.

So the test was defined as 5 adjustments per day, 365 days a year for 10 years with a 14 stone driver mass permanently on the seat. This equated to 18,250 adjustments. Millbrook Proving ground was chosen to conduct and validate the durability test.

Watch the Millbrook Proving Ground Drop Test

During the three weeks of accelerated life testing, Millbrook technicians monitored the performance of the unit for signs of wear or failures. We are pleased to say that following testing there were no failures and very little wear. We then decided to continue the testing to establish if the unit would fail and if so where.

The testing continued for a further 4,900 cycles until we ran out of our allotted testing time in the lab. This equated to a total of 12.5 years life testing, and again no failures and no significant wear.

The second test was to establish how robust and what impact the height adjuster would withstand. The units predecessor the SideRiser 1 was tested using ride data from buses tested at Millbrook.

This ride data showed that the maximum vertical acceleration the driver seat was exposed to was 1.5g through the base of the seat. So the SideRiser 1 was subjected to an accelerated life test of 5 years with the mass of a 30 stone driver including 4g vertical accelerations allowing for a margin of safety.

Despite passing this test we still experienced minor failures during service, indicating that the units were exposed to more severe accelerations during normal use. This could be as a result of pot holes, curb strikes, etc. The SideRiser 2 needed to be subjected to greater accelerations and to this end a drop test was chosen to indicate where the failure would be. Again Millbrook were chosen to conduct and verify the testing.

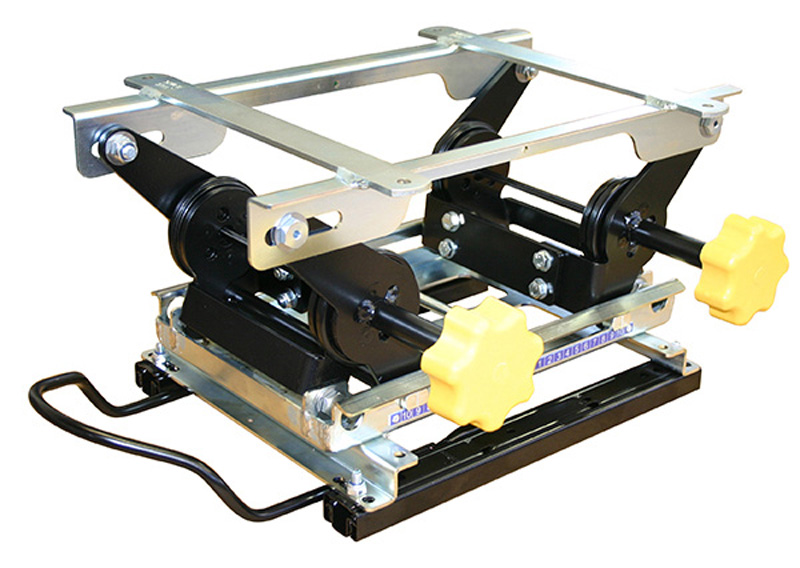

The picture on the left shows the SideRiser 2 set up with a test dummy with a mass of 30 stone. The agreed test was to drop the seat from ever increasing heights which would generate increasing G forces on the height adjuster. The starting height was 20mm which produced a 3g impact, the unit was then dropped from 25mm which produced 14g. Following these impacts the unit showed no signs of failure so it was agreed to increase the height significantly to 250mm. This drop produced a 157g impact and again no failures. We decided to go further; 500mm was the next drop height which produced a staggering 250g impact and the unit was still intact. We decided to call it a day and agreed the SideRider 2 was capable. The test unit was brought back to the factory and with the exception of a bent top frame, still works perfectly.